Lifting and Spreader Beams

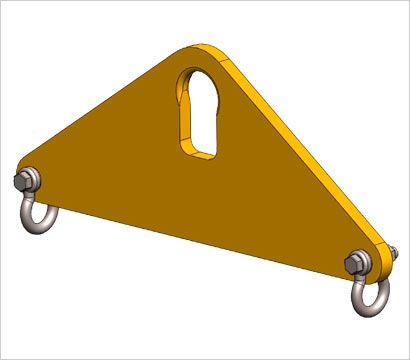

Lifting beams and spreader beams come in many sizes, styles and capacities. They are used in various applications where using conventional lifting slings are not an option due to angles, headroom issues, load sizes and/or position of lifting points.

Lifting beams generally built much heavier and usually have a single lifting point in the center of the beam and the connection points on the bottom end of the beam are usually placed towards the end of the beams for connecting your slings or connecting directly to your load. They come in either fixed or telescoping or other adjustment type options.

Spreader beams will typically have top rigging such as 2, 3 or 4 legged bridle sling connections on the top of the beam pick points usually directly over the underside pick points for lifting the load. This allows lighter beams to be used for spreader beam due to the multiple connection points over the underside of the beam pick points. They also come in either fixed or telescoping or other adjustment type options. Always ensure the spreader beams you are using are designed, engineered and built by a reputable manufacturer.

ASME B30.20 provides detailed information on the classifications, required markings, construction, installation, inspection, maintenance and operation for below the hook lifting devices. ASME BTH-1 provide information on the design criteria for below the hook lifting devices. Lifting and Spreader beams should be 100% tested to 125% of the rated capacity to ensure it will lift the load intended.

There is a lot of important information to check before ordering or using lifting and spreader beams such as inspections (initial, frequent and periodic), maintenance and operating practices to name a few.